- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

What is a Pressure Regulator Valve and How Does It Work?

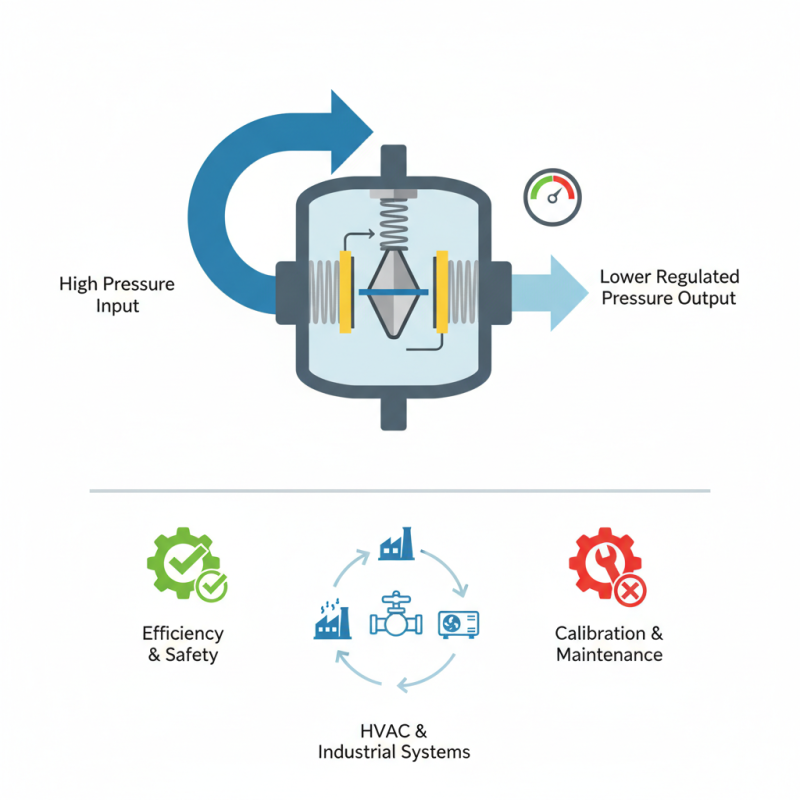

A Pressure Regulator Valve is crucial in any fluid or gas system. It controls the pressure, ensuring safety and efficiency. This valve adjusts the higher input pressure to a lower, usable level. Understanding its function can help prevent system failures.

In many applications, like HVAC systems or industrial machinery, the Pressure Regulator Valve plays a vital role. It maintains consistent pressure, which is key for performance. If the pressure fluctuates, it can lead to operational issues. Systems may not work as intended, wasting time and resources.

Yet, the Pressure Regulator Valve isn't perfect. Improper calibration can lead to inconsistent pressure. Regular maintenance is necessary to ensure optimal performance. Understanding these details can help operators reflect on the importance of this simple yet effective device.

What is a Pressure Regulator Valve?

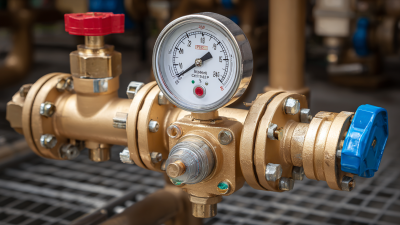

A pressure regulator valve is a crucial component in many systems. It ensures consistent pressure levels. This is vital in applications ranging from gas delivery to hydraulic systems. The main function of the valve is to control the pressure of a fluid, whether gas or liquid, flowing through a pipeline.

When fluids flow, they can create fluctuations in pressure. Without proper regulation, this can lead to system inefficiencies or failures. A pressure regulator valve helps to stabilize these pressures. It reduces high upstream pressure to a desired, lower downstream pressure. This process can sometimes be messy. Valve malfunctions may lead to pressure spikes or drops that affect system performance.

These valves come in various types and designs. Some are mechanical, relying on springs and diaphragms. Others operate electronically for precision control. However, choosing the right type can be challenging. Factors like the type of fluid, flow rate, and temperature need consideration. A mismatch can lead to subpar performance or damage. It is essential to evaluate your needs carefully before selection.

Key Components of a Pressure Regulator Valve

A pressure regulator valve is crucial for controlling fluid pressure in various systems. Key components include the diaphragm, spring, inlet, and outlet ports. The diaphragm responds to pressure changes, adjusting flow accordingly. The spring determines how much pressure is needed before the valve opens or closes. Inlet and outlet ports connect the regulator to the system.

The diaphragm is typically made of flexible materials. It needs to be durable yet sensitive enough to respond quickly. If it gets damaged, the regulator may fail, leading to inconsistent pressure levels. This can cause issues in applications like water supply and gas systems.

Tip: Regular maintenance of the diaphragm is essential. Check for wear and tear often. Replace it if you notice any signs of damage.

The spring plays a vital role. It’s crucial to select the right spring based on the application. An incorrect choice can lead to inefficient regulation. This could result in higher energy costs or even system failure.

Tip: Always consult with a professional when selecting components. Mistakes here can be costly.

Finally, ensure that inlet and outlet ports are securely connected. Loose connections can lead to leaks. Regular inspections can help identify these issues early.

Pressure Regulator Valve Characteristics

This bar chart displays key characteristics of a Pressure Regulator Valve, including diaphragm size, spring pressure, flow rate, operating temperature, and material strength. Each characteristic is essential for understanding the performance and applications of pressure regulators in various systems.

How Pressure Regulator Valves Function Mechanically

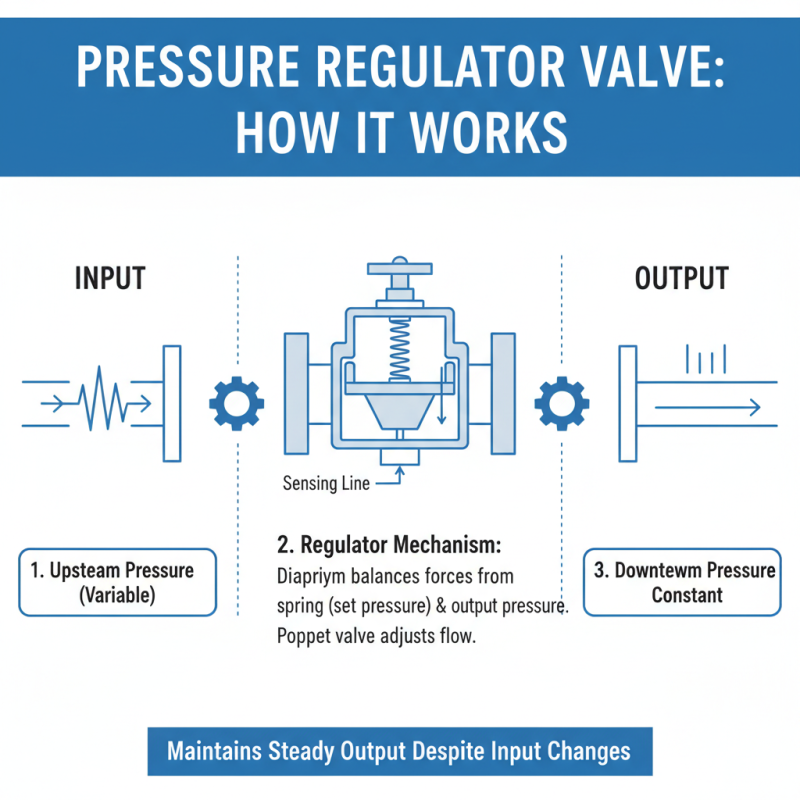

A pressure regulator valve controls the flow of gas or liquid. It maintains a steady output pressure, regardless of fluctuations in upstream pressure. Understanding how these valves work mechanically is essential for various applications.

These valves typically consist of a diaphragm and spring mechanism. When the inlet pressure rises, it pushes against the diaphragm. If the pressure exceeds the set limit, the diaphragm moves, compressing the spring. This adjustment allows the valve to throttle and reduce the output pressure. The process is precise but can sometimes fail if the components wear out or become dirty. Maintenance is crucial.

Tips: Regularly check the valve for leaks. Inspect the diaphragm for signs of wear. Consider installing filters to prevent dirt buildup.

In practice, not all systems function optimally. Misalignment during installation can lead to inaccurate pressure readings. It's important to evaluate performance regularly and make necessary adjustments. Being proactive can save time and resources.

Applications of Pressure Regulator Valves in Various Industries

Pressure regulator valves play a crucial role in many industries. In the gas industry, they control the pressure to ensure safe delivery. These valves help maintain stability in pipelines, preventing dangerous leaks. Regulating pressure in these systems is essential for both safety and efficiency.

In the manufacturing sector, pressure regulators are vital for pneumatic systems. They maintain consistent pressure for tools and machinery. This consistency enhances performance and reduces wear on equipment. However, not all systems operate flawlessly. Sometimes, improper calibration can lead to inconsistent output. More attention is needed to ensure these regulators function optimally.

In water treatment facilities, pressure regulators manage water flow and quality. They help maintain pressure for various processes, ensuring effective filtration. However, neglecting regular maintenance can result in pressure spikes. Such issues can compromise water quality and system integrity. Each industry must be vigilant about these critical components.

What is a Pressure Regulator Valve and How Does It Work? - Applications of Pressure Regulator Valves in Various Industries

| Industry | Application | Pressure Regulation Requirement | Key Benefits |

|---|---|---|---|

| Oil & Gas | Pipeline transport | Maintaining pipeline pressure | Safety and efficiency |

| Manufacturing | Hydraulic systems | Consistent hydraulic pressure | Enhanced machinery performance |

| Food Processing | Beverage filling | Maintaining consistent filling pressure | Product quality assurance |

| Pharmaceuticals | Liquid dispensing | Accurate dispensing pressure | Precision in formulation |

| Aerospace | Control systems | Regulated cabin pressure | Safety and comfort during flight |

Common Issues and Maintenance Tips for Pressure Regulator Valves

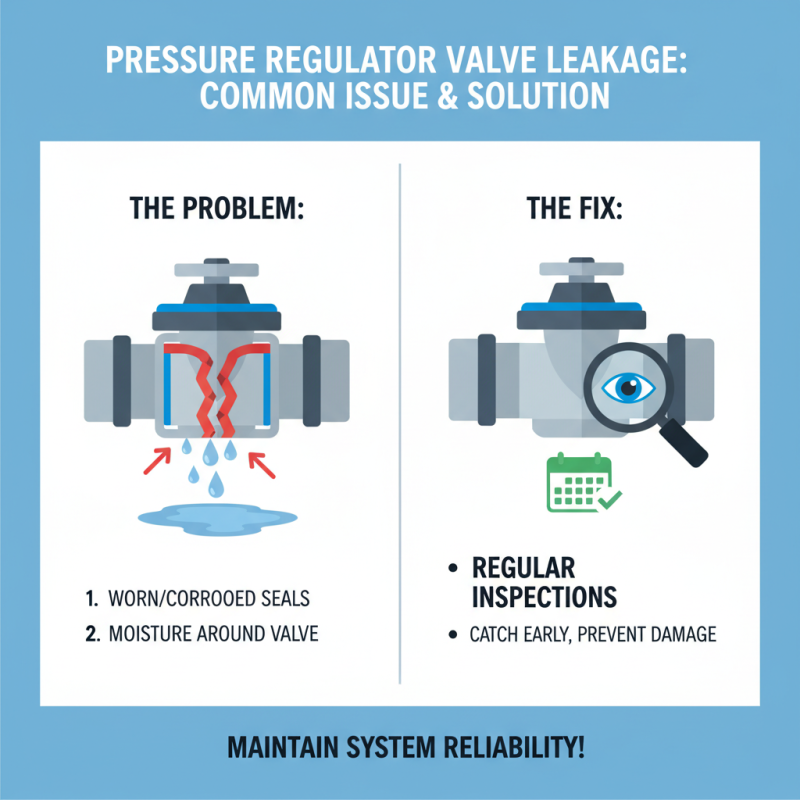

Pressure regulator valves are crucial in maintaining consistent pressure in various applications. However, they can face common issues over time. One such problem is leakage. This occurs when seals wear down or corrode. Regular inspections can help catch this early. You may notice moisture around the valve. Address it promptly to avoid larger issues.

Another issue is fluctuation in pressure. This can stem from dirt or debris clogging the valve. Cleaning the valve regularly can help prevent this. Inspect filters and screens to ensure they’re clear. Consider using a fine-mesh filter upstream. It acts as a first line of defense against contaminants.

Maintenance is key to longevity. Lubricating moving parts can prevent sticking. Always use the recommended lubricant for your system. Don’t overlook scheduled service checks. They can reveal underlying problems before they escalate. Pay attention to the sound of the valve. Unusual noises can signal issues needing further inspection. Taking these simple steps can ensure your pressure regulator valve operates smoothly.

Related Posts

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

10 Reasons Pressure Regulator Valve is Essential for Industrial Applications

-

Understanding the Essential Role of Pressure Regulator Valves in Industrial Applications

-

Top Reasons Why a Pressure Regulator is Essential for Your Gas or Liquid System

-

Top Strategies for Maximizing Efficiency with High Pressure Regulators

-

How to Choose the Right Pressure Regulator for Your Industrial Needs