- Products

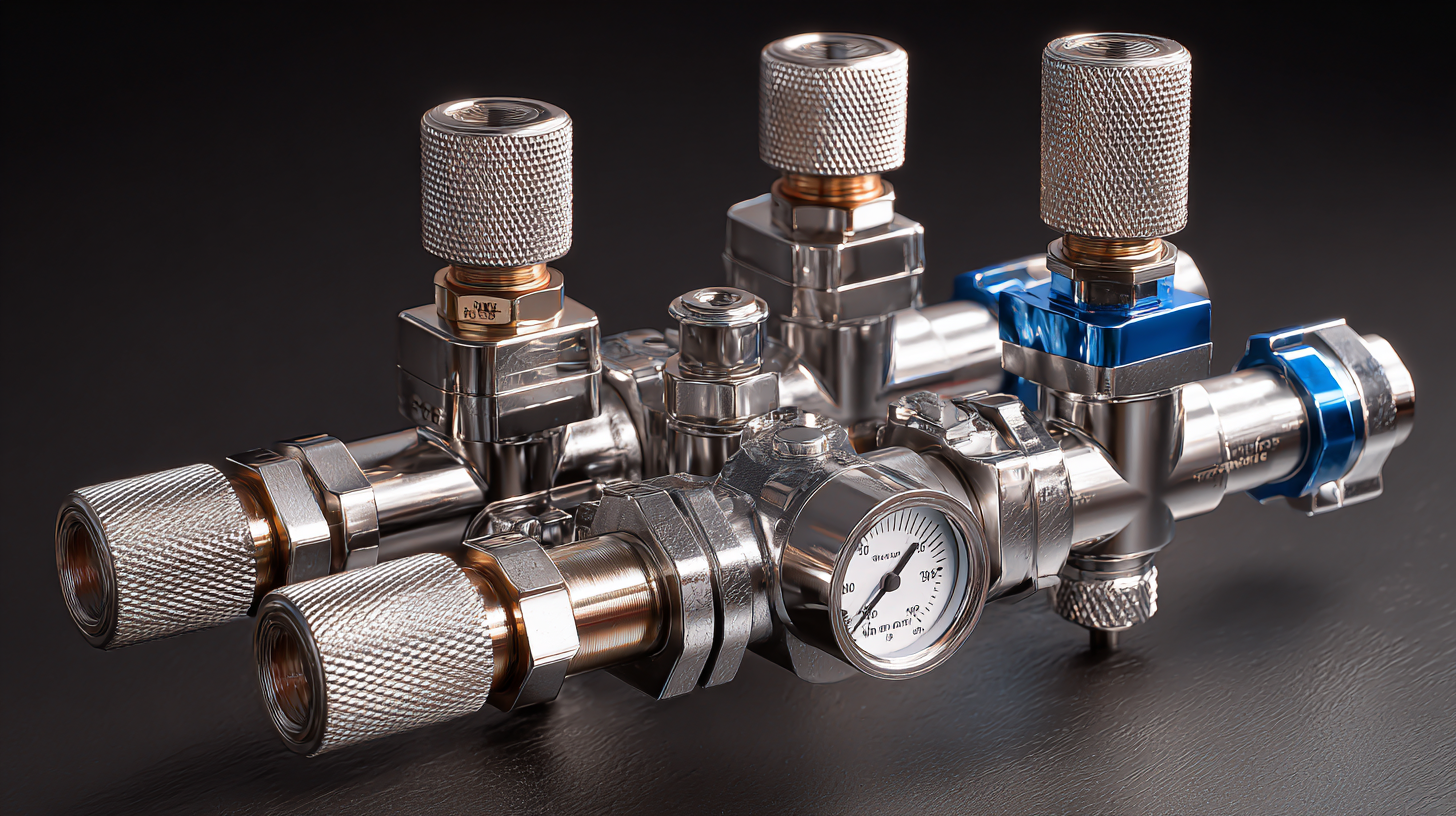

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

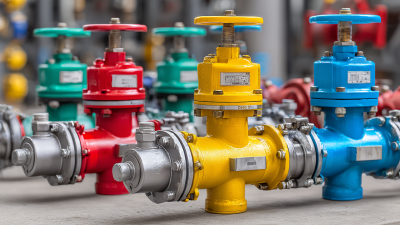

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

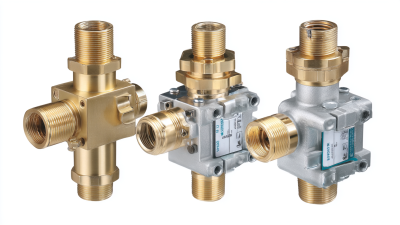

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

Identifying Common Issues with Gas Regulators: Ensuring Safety and Efficiency in Your System

Gas regulators play a crucial role in maintaining the safety and efficiency of gas systems, yet they often encounter a variety of common issues that can compromise their performance. Understanding these potential problems is essential for ensuring that your gas systems operate smoothly and safely. In this blog, we will explore five critical issues that can arise with gas regulators, including leaks, pressure fluctuations, and mechanical failures. Additionally, we will delve into the reasons behind these problems and highlight the key steps you can take to prevent them. By identifying and addressing these common challenges, you can enhance the reliability of your gas systems and ensure the safety of your operations.

Join us as we examine these aspects of gas regulators to improve your system's functionality and longevity.

Common Symptoms of Faulty Gas Regulators

Gas regulators play a crucial role in controlling the flow and pressure of gas within your system. However, identifying common symptoms of faulty gas regulators can prevent safety hazards and ensure optimal performance. One major sign of a malfunctioning regulator is inconsistent gas pressure, which can lead to irregular appliance performance. If you notice that your appliances frequently turn off or fail to ignite, this may indicate an issue with the regulator.

Gas regulators play a crucial role in controlling the flow and pressure of gas within your system. However, identifying common symptoms of faulty gas regulators can prevent safety hazards and ensure optimal performance. One major sign of a malfunctioning regulator is inconsistent gas pressure, which can lead to irregular appliance performance. If you notice that your appliances frequently turn off or fail to ignite, this may indicate an issue with the regulator.

Another symptom to watch for is the presence of gas leaks. If you detect the smell of gas near the regulator or hear a hissing sound, immediate action is necessary. Gas leaks not only pose a safety risk but can also cause increased energy costs. Regularly inspecting connections and seals can help mitigate these risks.

Tips for maintaining your gas system include scheduling routine checks with a certified technician, particularly if you notice symptoms like unusual sounds or erratic pressure. Additionally, always ensure that your regulator is compatible with your gas appliances, as mismatches can compromise safety and efficiency. Keeping an eye on these key indicators will help maintain a safe and efficient gas system.

Causes of Gas Pressure Fluctuations

Gas pressure fluctuations can pose significant risks to both safety and efficiency in any system utilizing gas regulators. These fluctuations may arise from various factors such as demand changes, temperature variations, and equipment malfunctions. When there is an abrupt shift in the demand for gas—like when multiple appliances are turned on simultaneously—it can overwhelm the regulator’s ability to maintain a steady pressure, leading to undesirable spikes or drops in gas flow.

Another common cause of gas pressure fluctuations is temperature changes. As the gas heats up, it expands, potentially increasing the pressure within the system. If the regulator does not adequately adapt to these changes, it can lead to inconsistent gas delivery, affecting the performance of appliances. Additionally, wear and tear on the regulator itself can result in internal leaks or blockages, further contributing to pressure inconsistencies. Regular maintenance and inspections are crucial in identifying these issues early, ensuring the regulator operates smoothly and safely, thereby enhancing the overall efficiency of the gas system.

Identifying Common Issues with Gas Regulators: Ensuring Safety and Efficiency in Your System - Causes of Gas Pressure Fluctuations

| Issue | Description | Potential Causes | Impact on System | Mitigation Strategies |

|---|---|---|---|---|

| Pressure Fluctuations | Variations in gas pressure delivered to the system. | Regulator malfunction, demand changes, supply line issues. | Increased wear on equipment, inefficiency in operations. | Regular maintenance, gauge monitoring, adjusting regulator settings. |

| Gas Leaks | Unintentional release of gas from the system. | Worn seals, loose fittings, damaged pipes. | Safety hazards, costly wastage, environmental concerns. | Regular inspections, using leak detection equipment, tightening connections. |

| Inadequate Flow | Insufficient gas supply to meet demand. | Clogged filters, undersized regulators, low supply pressure. | Operational inefficiencies, potential shutdowns. | Upgrading system components, regular cleaning, monitoring flow rates. |

| Temperature Variations | Changes in temperature affecting gas density and pressure. | Environmental factors, lack of insulation, heat sources nearby. | Impact on pressure consistency, potential freeze-ups in regulators. | Insulating pipelines, using temperature compensation techniques. |

Signs of Leaks and Their Implications on Safety

When it comes to gas regulators, safety should always be the top priority. A subtle odor or hissing sound can be indicative of leaks, which not only compromise the efficiency of your system but also pose serious risks to both property and personal safety. Recognizing these signs early can help prevent catastrophic failures or accidents.

Regular checks and maintenance are critical in identifying any signs of wear or damage to your regulators, enabling you to address issues before they escalate.

In a world increasingly reliant on technology, the approach to safety must also adapt. Just as companies face threats from cyber attacks that can disrupt operations and compromise sensitive information, residents must be vigilant about the physical dangers surrounding their gas systems. Ensuring that your gas regulators are functioning properly and free of leaks is essential in maintaining operational integrity. By staying informed and proactive, you safeguard not only your home but also contribute to a broader culture of safety.

Preventive Maintenance Tips to Extend Regulator Life

Preventive maintenance is essential for ensuring the longevity and efficiency of gas regulators. According to the American Gas Association’s 2021 report, improper maintenance can lead to a 15% reduction in system efficiency, which not only increases operational costs but can also pose safety hazards. Regular inspections and timely servicing are vital in proactively identifying any issues, preventing costly downtime and safety incidents.

Tip: Schedule routine inspections every three to six months, focusing on checking for corrosion, leaks, and proper pressure regulation. Utilizing advanced diagnostic tools can significantly aid in detecting early signs of wear and tear, ensuring the regulator operates within safe parameters.

Additionally, keeping the regulator clean and free from debris can enhance its performance. The National Fire Protection Association recommends that systems should be routinely cleared of any obstructions or build-ups that could hinder the regulator’s function.

Tip: Implement a clean-up routine during every maintenance check, ensuring that areas around the regulator are accessible and free from any blockages. This vigilance not only prolongs the regulator's life but also contributes to a safe operational environment.

Best Practices for Installing and Testing Gas Regulators

When it comes to installing gas regulators, following best practices is crucial to ensuring both safety and efficiency. First and foremost, proper selection of the regulator is essential. This involves assessing the type of gas being used, the required pressure levels, and the capacity needs of your system. Using the right regulator not only enhances performance but also minimizes risks associated with gas leaks or pressure variances.

Once the correct regulator is selected, installation should be conducted with care. It is important to ensure that all connections are secure and free from any corrosion or damage. Utilizing the manufacturer’s guidelines during installation can help prevent common pitfalls. Additionally, testing the system post-installation is a vital step. Perform pressure tests to confirm that the regulator functions as intended, and regularly inspect the system for any signs of wear or irregularities. Implementing these best practices will greatly contribute to the safe and efficient operation of your gas system, ensuring peace of mind for users.

Gas Regulator Issues Overview

This chart illustrates the common issues encountered with gas regulators, highlighting the frequency of each issue in order to promote safety and efficiency in installation and testing practices.

Related Posts

-

Navigating Import and Export Certifications for the Best Gas Regulators in the Market

-

Mastering High Pressure Regulation: A Step-by-Step Guide to Choosing the Best Regulator

-

Unlocking Performance: Key Technical Specifications of the Best Back Pressure Valve for Global Buyers

-

10 Essential Reasons to Choose the Best Gas Regulator Valve for Your Needs

-

Future Trends in Best Flow Valve Market Analysis for 2025 Industry Outlook

-

Top 5 Innovative Applications of the Best High Pressure Regulators in Various Industries