- Products

- Pressure Reducing Regulators

- Back Pressure Regulators

- Tank Blanketing Valves

- Temperature Regulators

- Industrial Control Valves

- Wafer Style Control Valves

- JCVS Industrial Control Valves

- Globe Style/Cage Guided Control Valves

- Mixing/Diverting Control Valves

- Motor Operated Control Valves

- Valve Positioners & Accessories

- Applications

- Resources

- Find a Sales Rep

- Brands

2026 Best Slide Gate Valve Types and Features Explained?

In the evolving landscape of industrial valves, the Slide Gate Valve stands out with unique features and applications. Expert James Thornton, a leading voice in fluid control technology, emphasizes, "Understanding Slide Gate Valves can significantly enhance operational efficiency." This highlights their critical role in various industries.

Slide Gate Valves provide a reliable solution for managing the flow of materials and liquids. Their design allows for easy operation and maintenance. However, choosing the right type among the various options can be daunting. Factors like size, material, and sealing mechanisms come into play, impacting performance.

Despite their advantages, Slide Gate Valves are not without challenges. Misalignment and wear can affect functionality. Regular inspections and maintenance are essential to ensure optimal performance. As companies aim for efficiency, addressing these issues is crucial. The journey in selecting and maintaining Slide Gate Valves can lead to both success and setbacks.

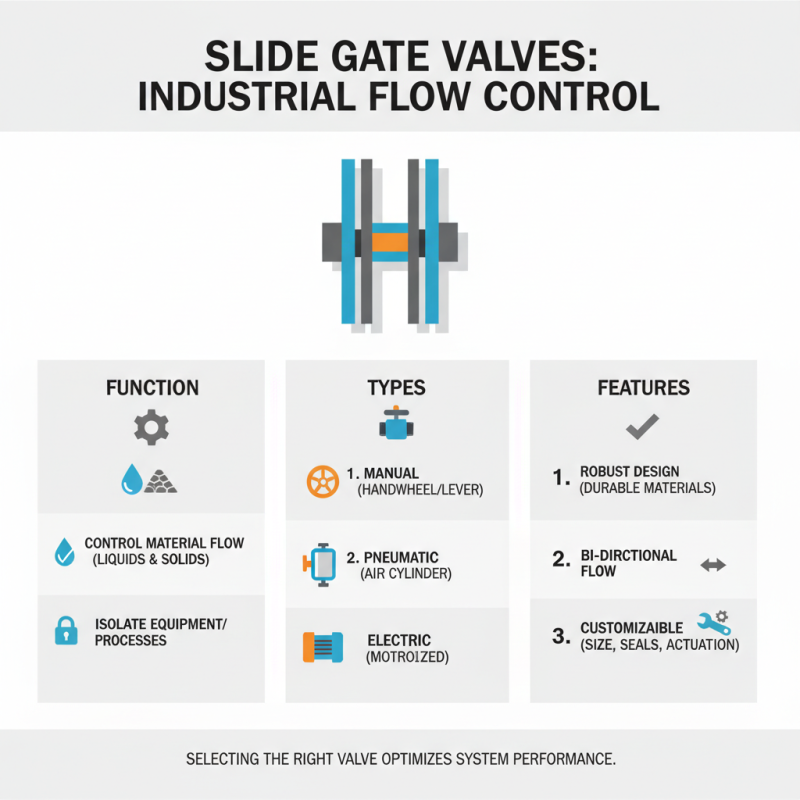

Types of Slide Gate Valves: An Overview

Slide gate valves are essential in various industrial applications. They control the flow of materials, such as liquids or solids, in diverse systems. Understanding the different types and features of slide gate valves is crucial for selecting the right one for specific needs.

There are several types of slide gate valves. Manual slide gates are straightforward and easy to operate. However, they may not be efficient in high-demand situations. Automated slide gates offer enhanced control and precision. They reduce the need for manual intervention but can be complex to maintain. Another type is the pneumatic slide gate valve, which uses compressed air for operation. While effective, reliance on air systems can lead to unexpected failures.

Each type has its pros and cons. The choice often depends on the application and specific requirements. For example, an automated valve can improve efficiency but also introduces new failure points. Users must consider these factors for optimal performance.

Key Features of Slide Gate Valves

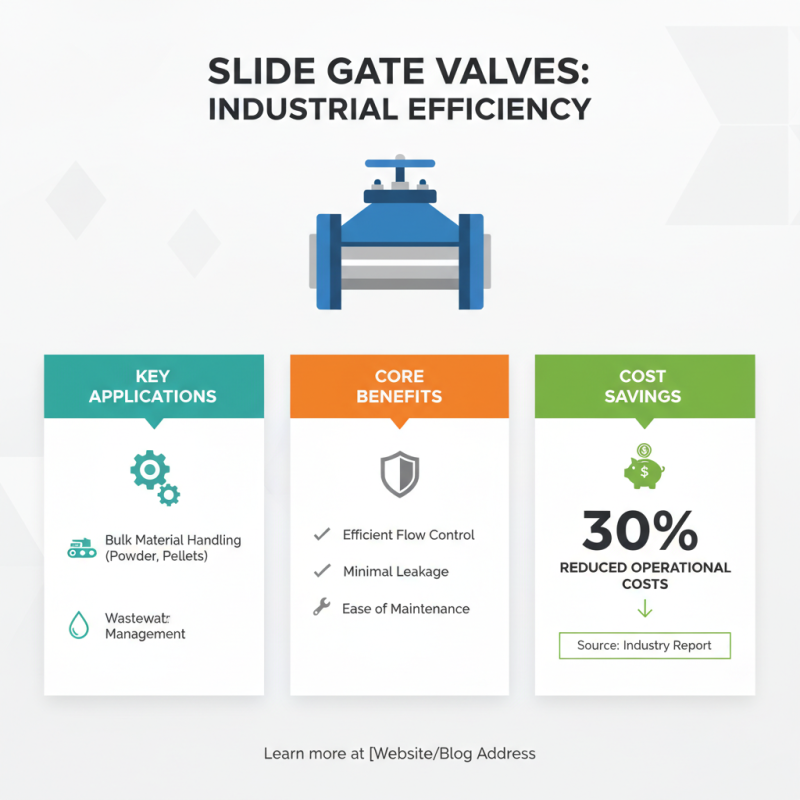

Slide gate valves are critical components in various industries, particularly in bulk material handling and wastewater management. Their design focuses on efficient flow control, ensuring minimal leakage and ease of maintenance. According to a recent industry report, slide gate valves can reduce operational costs by up to 30% when properly utilized.

One key feature of slide gate valves is their ability to handle a wide range of materials, from granular solids to liquids. This versatility is essential in processing plants and mining operations. The robust construction of these valves allows them to withstand harsh conditions, yet they require regular maintenance. A study highlighted that neglecting maintenance can lead to a 25% decrease in valve efficiency over time.

Another notable aspect is the sealing capability. Many slide gate valves use enhanced sealing technology to minimize backflow and leakage, improving sustainability. However, choosing the right material for the sealing element can be challenging. Manufacturers often face dilemmas regarding the balance between cost and performance. Finding the ideal solution requires thorough testing and adaptation.

Applications of Slide Gate Valves in Various Industries

Slide gate valves are crucial in various industrial applications. They provide efficient flow control in bulk material handling systems. These valves are often used in mining, cement, and power generation sectors. Research shows that the demand for slide gate valves in these industries is expected to grow by 4.5% annually through 2026.

In the mining sector, slide gate valves manage the flow of ores and minerals. They help minimize dust emissions and improve safety. In cement production, these valves ensure that materials flow smoothly to crushers and mixers. However, one challenge is wear and tear due to abrasive materials. Regular maintenance is necessary to prevent downtime.

Power generation facilities also rely on slide gate valves. They manage the flow of coal or biomass fuels. Properly functioning valves enhance efficiency and reduce operational costs. Yet, improper installation can lead to leaks. This highlights the need for skilled technicians during setup. Awareness of these issues can lead to improved performance in various applications.

Installation and Maintenance Best Practices

Installing and maintaining slide gate valves requires careful attention to detail. Proper alignment is crucial. Misalignment can lead to wear and decreased efficiency. According to industry data, misaligned valves can cause a 15% drop in performance over time. Ensure that your valve is correctly aligned during installation to avoid future issues.

Regular inspections are essential. Check for signs of wear or corrosion. The recommended interval for inspections is every six months. Look for leaks and ensure seals are intact. A study by the American Society of Mechanical Engineers indicates that 25% of valve failures result from inadequate maintenance. Don't overlook the importance of lubrication. Proper lubrication reduces friction and prolongs valve life.

After installation, document the process. Keep records of maintenance activities. This helps track valve performance and understand trends. Consider using condition monitoring tools. These can alert you to changes in valve behavior. Often, we take maintenance for granted. Recognizing the potential for decline can change that mindset. Regular upkeep ensures optimal performance and extends service life.

Comparative Analysis of Slide Gate Valve Materials and Designs

When considering slide gate valves, material choice is critical. Common materials include stainless steel, cast iron, and plastic composites. Stainless steel offers corrosion resistance, but it can be costly. Cast iron is more affordable but may not withstand corrosive environments. Plastic composites excel in lightweight applications but may lack durability in heavy-duty scenarios. Each material has strengths and weaknesses, complicating the selection process.

Design aspects also play a significant role. Slide gate valves can vary in dimensions, sealing methods, and operational mechanics. Research indicates that a well-designed valve can improve operational efficiency by up to 25%. However, improper design can lead to frequent failures. One study revealed that nearly 30% of valve failures are due to poor design choices. Understanding the balance of material and design is essential for optimal performance in specific applications.

Related Posts

-

Understanding Industry Standards for Best Slide Gate Valve Manufacturing Processes

-

How to Choose the Right Pressure Reducer for Your Needs

-

The Ultimate Guide to Understanding Water Pressure Regulators: How They Enhance Your Plumbing System

-

How to Choose the Right Natural Gas Regulators for Your Home Needs

-

How to Optimize Your System with Flow Regulator Valves for Maximum Efficiency

-

How to Choose the Right Pressure Regulator for Your Industrial Needs